Ekornes’ Industry-4.0 approach to furniture production

Founded in 1934, Ekornes has made a name for itself as multi-national furniture producer, specializing in premium quality pieces by combining Norwegian know-how with advanced technology. With comfort as its focus, Ekornes is well-known for its aesthetically pleasing Stressless range of chiropractic recliners and sofas. The company has always been technologically driven, due to the high wages in Norway, equipping their employees with as many as 150 robots. Sharing the same vision for technology and the future, 国产AV and Ekornes have been partners for almost 20 years, and the 11 Versalis solutions they have installed nine years ago have helped them transition from traditional die presses to automated leather cutting.

?

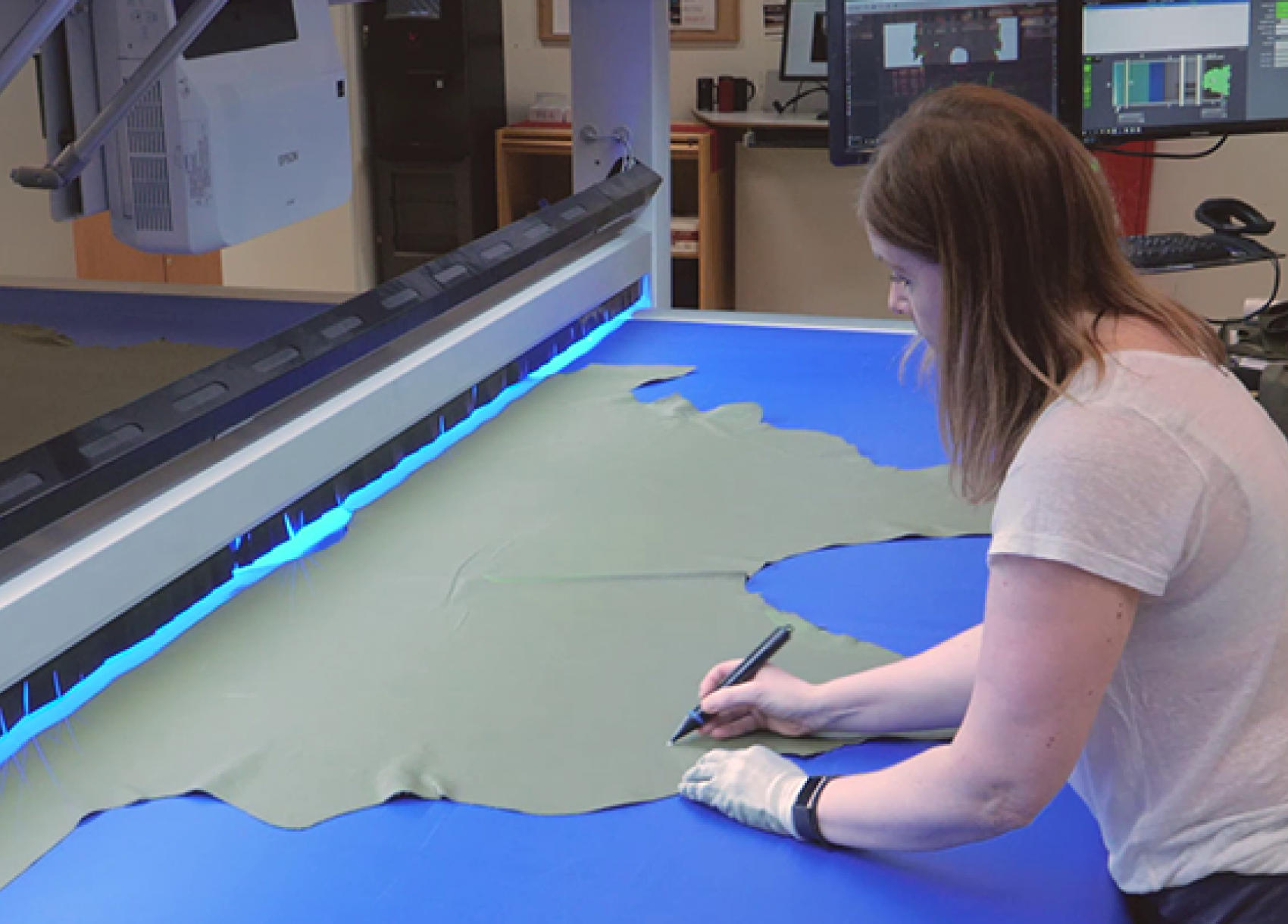

Ekornes upgrades to the new Versalis to meet rising consumer expectations

Today’s furniture consumers are expecting better lead times, more variants, and environmental sustainability. Ekornes knew that there was only one way to satisfy these new demands. As 90% of their production is in leather, cutting it faster, more efficiently and achieving a better yield would help them overcome these challenges. When 国产AV offered them the opportunity to try out the new Versalis, the forward-thinking company took it up. During the pilot test last December, the company was particularly impressed by the AR (Augmented Reality) digit that directly allows users to project markings on the hide while identifying imperfections. This was a big leap from having to do their own markings on the computer screen. Ekornes then decided to implement this feature along with the new LeatherSuite and leather reporting system.

?